Precision Metal Forming

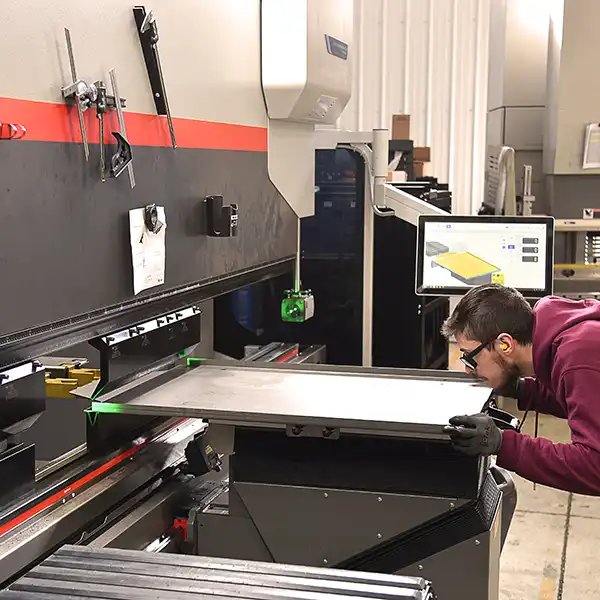

At Flextur, we don’t just bend metal— we provide solutions that enhance strength, precision, and efficiency. With our advanced press brakes equipment, we provide accurate, repeatable results for industries requiring durable, well-formed metal components. Whether you need complex bends, large-scale production, or custom fabrication, our forming capabilities ensure superior performance and efficiency.

Capabilities That Set Us Apart:

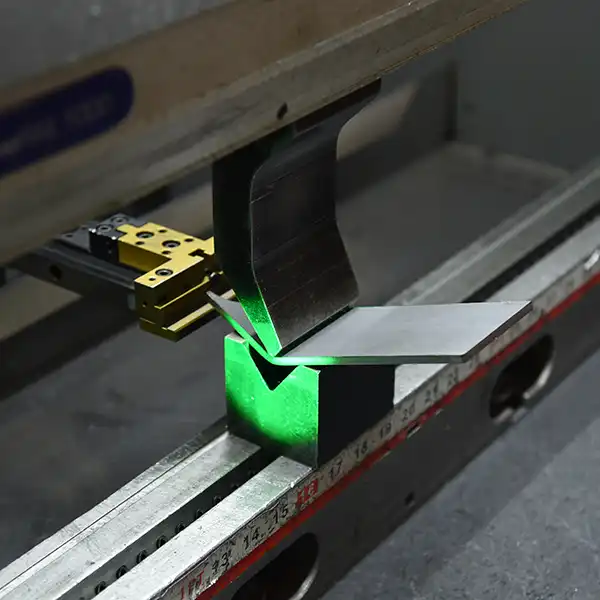

- Press Brake Forming: Achieve high-precision bends with multi-axis control and dynamic crowning for consistent angle accuracy.

- Custom Forming Solutions: Tailored metal shaping for specialized applications in various industries.

- High-Volume Production: Our streamlined processes ensure fast turnaround times for large-scale projects without sacrificing quality.

- Prototyping and Small Runs: Need a test part or a small production run? We’ve got you covered.

Benefits of Partnering with Flextur

Advanced Equipment & Expertise

Our press brakes and rollers allow for tight tolerances, repeatability, and superior part fit-up.

Cost-Effective Solutions

Minimize material waste and optimize forming efficiency for better cost savings.

Scalability & Flexibility

From prototyping to high-volume runs, we adapt to your production needs.

Customer-Centric Approach

We work closely with you at every stage, ensuring your vision becomes a reality.

Fast Turnaround

Our efficient processes and skilled team minimize lead times, keeping your project on schedule.

Broad Material Expertise

From stainless steel and aluminum to specialty metals, we handle a variety of materials with ease and precision.

Our Equipment

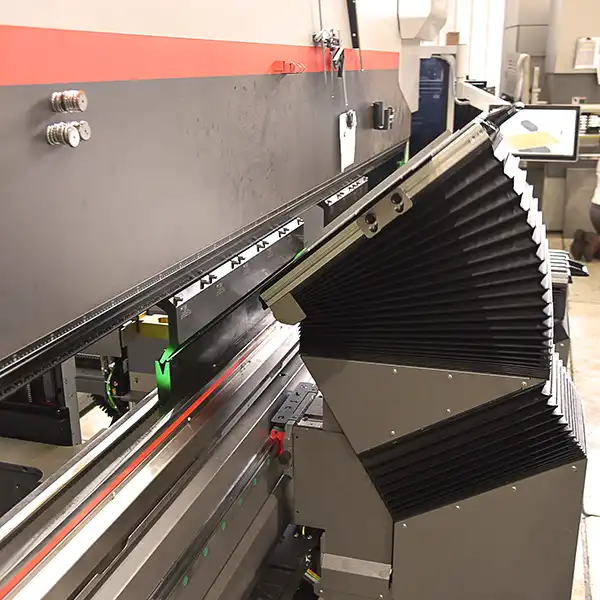

Bystronic Xact 225 Press Brake

- Byvisions Bending Control

- CNC Controlled Hydraulic Crowning

- Hydraulic Upper Tool Clamping

- 5 Axis Backgauge

- 225 Tons of Pressure

Bystronic Xpert 40 Press Brake

- High-Speed Bending

- 3 Axis Backgauge

- 44 Tons of Pressure

Bystronic Xpert Pro 320 Press Brake

- Dynamic Hydraulic Crowning

- Laser Angle Measurement System

- 6 Axis Backgauge

- Built-In Bending Aids

- 345 Tons of Pressure

- Bend 14 feet of 1/4” material or 9 feet of 3/8” material

Frequently Asked Questions

We work with a variety of materials, including mild steel, stainless steel, and aluminum ensuring high-quality results for different industries.

With 345 tons of pressure, our press brakes can accommodate 14 feet of ¼” material or 9 feet of 3/8” material.

With advanced features like dynamic crowning and laser angle measurement systems (LAMS), we maintain tight tolerances, ensuring consistent bend accuracy within ±0.5 degrees.

Yes! We specialize in tailored solutions based on your design requirements and specifications.

Our metal forming services support industries such as heavy equipment, agriculture, construction, industrial manufacturing, and more.