Introducing the Bystronic Xpert Pro 320 Press Brake: Unmatched Precision & Power

At Flextur, we strive to be a leader in the manufacturing industry through innovation and efficiency. The latest addition to our lineup, the Bystronic Xpert Pro 320 Press Brake, reflects this commitment. Designed for high-performance fabrication, this advanced press brake enhances accuracy, boosts productivity, and ensures superior quality while reinforcing our commitment to excellence at every stage of the manufacturing process.

Key Features and Benefits

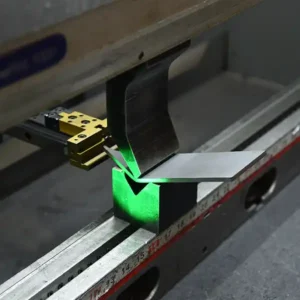

1. Laser Angle Measurement System

The Xpert Pro 320’s advanced Laser Angle Measurement System (LAMS) allows us to form parts with greater accuracy. Using laser sensors, it measures the actual angle during the bending process and if the measurement deviates from the programmed angle due to material variations, LAMS automatically adjusts the punch position and bends again resulting in accurate and consistent bends each time.

2. Dynamic Hydraulic Crowning

The dynamic hydraulic crowning feature eliminates angle variations across longer bends by compensating for deflection. Multiple hydraulic cylinders in the lower beam apply counter-pressure, ensuring uniform angles from the first part to the last.

3. 6 Axis Backgauge

This system allows for complex and multi-dimensional positioning of the workpiece. Unlike traditional backgauges, the 6 independent axes can move in different directions making it ideal for intricate bending sequences.

4. Built-In Bending Aids

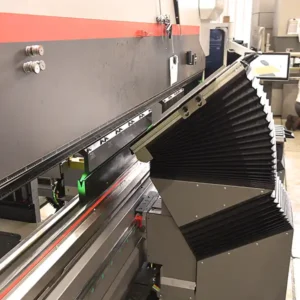

The built-in bending aids simplify handling of large parts. Using motorized arms that move in sync as the brake applies force, they help lift and guide the material. Not only does this reduce the need for operators to manually support the parts, but it also prevents sagging and deformation.

5. Size & Strength

With the power to bend 14 feet of 1/4” material or 9 feet of 3/8” material, the Xpert Pro 320 significantly expands our capabilities. The 345 tons of pressure also allows us to form thicker materials with ease.

Customer Benefits and Competitive Edge

Investing in the Xpert Pro 320 strengthens our ability to meet customer demands for precision and efficiency. One early success involved a project where the advanced LAMS technology ensured perfect angles and fit-ups, which reduced welding adjustments and enhanced overall quality for the project.

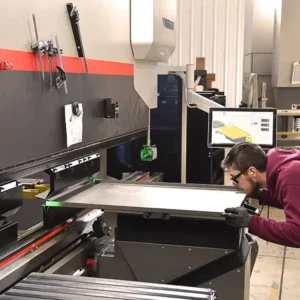

Seamless Implementation and Operator Experience

From delivery to fully operational, getting the Xpert Pro 320 up and running was a collaborative effort. Moving equipment of this scale required a highly skilled team to handle the logistics and installation. While setup involved minor troubleshooting with the Bystronic team, our operators’ experience with other Bystronic brakes made the transition smooth.

"Running the Xpert Pro 320 is actually really fun. It holds tighter tolerances, which means less checking and adjusting so that saves us a lot of time. The LAMS, dynamic crowning, and bending aids make a huge difference—not just in how easy it is to run but also in how well the parts fit up downstream, especially in welding. We’re already seeing faster run times and better part quality. It’s just a solid machine that makes my job easier and helps us turn out better products in less time." -Robert Miller, Fab Process Engineer, Flextur

Boosting Production Efficiency

Although it’s only been operational for a few weeks, we’ve already seen promising results. Early estimates indicate a 10-25% improvement in forming times and a reduction in downstream processes such as welding by up to 20%, thanks to tighter tolerances resulting in better part fit-ups. These benefits translate to faster project completion and higher-quality outcomes for our customers.

Additionally, the Xpert Pro 320 is enabling us to:

- Handle R&D projects with greater agility and speed.

- Take on larger, more complex parts.

- Maintain tighter tolerances for demanding customer specifications.

Positioning for the Future

The Bystronic Xpert Pro 320 is more than just a machine; it’s a cornerstone of our growth and development strategy. By equipping our facility with state-of-the-art technology, we’re not only enhancing our current capabilities but also laying the foundation for future innovation. Several upcoming projects will showcase the Xpert Pro 320’s full potential, enabling our team to take on larger-scale projects with greater efficiency.

Ready to see how the Xpert Pro 320 can benefit your next project? Contact us today to learn more about our metal forming services >>